TYPES OF DYNAXE SEATS

Type:

Elastomer in: NBR, EPDM or Vitón

Characteristics:

Elastomer seal in: NBR, EPDM or Vitón

Type:

Reinforced PTFE (fire safe)

Characteristics:

Loaded with fiberglass, cardboard, graphite and live load. With additional ring option, which ensures the tightness under fire conditions

Type:

RTFE

Characteristics:

Loaded with fiberglass, cardboard, graphite and live load

Type:

METAL-METAL

Characteristics:

Preloaded and profiled metal seal, in both directions

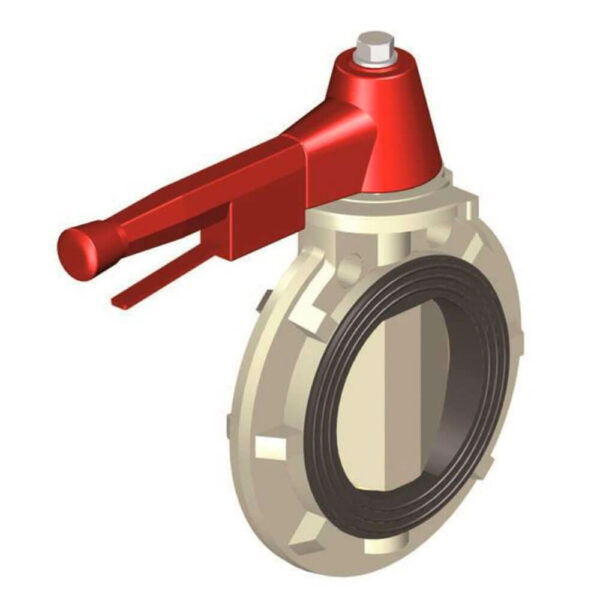

DESCRIPTION OF DYNAXE CHARACTERISTICS:

Zero Leakage : Zero leakage solutions for pressures higher than 50 bar and, depending on the material, for temperatures from 50 to 540°C

Seat in disk:

Unlike the majority of the designs, Dynaxe has a built-in seat in the disk and not in the body of the device, resulting in the following:

- higher tightness

- single-pieced body

- better safety

- reduced number of components

Anti-static design: Due to its sophisticated design, all the double eccentricity butterfly valves are intrinsically anti-static.

These parts also comply with the requirements of the chemical and petrochemical industries.

Double disk: For valves starting from 10″-150# and 6-300#, Dynaxe is equipped with a twin disc, which optimizes (increases) Cv and, therefore, with better operational costs.

Applications: + Hydrocarbon and natural gas carbons + Gas-to-burner systems + Cooling + Residual and drinking water systems + Firefighting systems, steam and condensed systems, mining, etc.

Reviews

There are no reviews yet.